Whether you’re a homeowner dreaming of a basketball court in your basement or a facility manager upgrading an entire gymnasium, the leap from basic flooring to professional-grade hardwood represents more than just an aesthetic choice. It’s an investment in performance, durability, and long-term value that requires careful planning and expert execution.

Professional court hardwood flooring differs significantly from residential options. While your living room hardwood needs to withstand foot traffic and occasional spills, pro court flooring must endure intense athletic activity, maintain consistent ball bounce, and provide optimal traction for player safety. The wood species, installation techniques, and maintenance requirements all shift dramatically when you’re building a surface that athletes will rely on for peak performance.

Modern innovations in hardwood flooring technology have revolutionized the industry. COPOSPORTS biomass sport wooden flooring represents the cutting edge of this evolution, combining traditional hardwood beauty with advanced biomass technology. This sustainable approach not only delivers exceptional performance but also addresses environmental concerns that increasingly influence flooring decisions.

Understanding the transition from standard hardwood to professional court flooring requires knowledge of materials science, installation expertise, and long-term maintenance strategies. The following guide reveals the industry secrets that separate amateur installations from professional-grade results.

The Foundation: Why Quality Materials Make All the Difference

Professional court hardwood flooring installation begins long before the first plank touches the subfloor. The material selection process determines every aspect of your court’s future performance, from ball bounce consistency to long-term durability under extreme conditions.

Wood type selection extends beyond aesthetics. Maple dominates professional courts because its dense grain structure provides consistent hardness across the entire surface. This uniformity ensures that a basketball bounces the same height whether it hits the center court or near the sidelines. Oak, while beautiful and durable for residential use, exhibits grain variations that can create inconsistent playing surfaces.

Subflooring preparation separates professional installations from amateur attempts. Pro court flooring requires engineered subfloor systems that incorporate moisture barriers, shock absorption, and dimensional stability. These systems typically include multiple layers: a concrete foundation, moisture barrier, insulation layer, and engineered subfloor panels designed specifically for athletic applications.

Finish selection impacts both performance and maintenance. Professional court finishes must provide slip resistance without becoming sticky, resist scuff marks from athletic shoes, and maintain their properties through frequent cleaning with commercial-grade equipment. Standard residential polyurethane finishes simply cannot withstand this level of abuse.

Expert Hardwood Installation Tips for Flawless Results

Professional court hardwood flooring installation follows precise protocols that eliminate common failure points. These flooring installation tips represent decades of industry experience distilled into actionable steps.

Climate control during installation prevents future problems. Wood installation requires maintaining consistent temperature and humidity levels throughout the process. Professional installers monitor these conditions continuously, adjusting HVAC systems to maintain optimal ranges. This attention to environmental factors prevents expansion and contraction issues that plague amateur installations.

Expansion gap calculation requires mathematical precision. Professional court installation accounts for seasonal wood movement across large surfaces. Unlike residential rooms where small gaps suffice, courts require calculated expansion zones that maintain structural integrity without compromising playing surface continuity.

Fastener selection and placement follow engineering specifications. Pro court flooring uses specialized fasteners designed for athletic applications. The spacing, angle, and depth of each fastener affects long-term stability. Professional installers use pneumatic nailers calibrated for specific wood species and subfloor combinations.

Subfloor inspection identifies potential issues before they become expensive problems. Professional contractors examine every square inch of the subfloor, checking for levelness, moisture content, and structural integrity. This thorough inspection prevents callbacks and ensures warranty compliance.

Choosing the Right Wood: Maple, Oak, and Beyond

Hardwood court flooring selection involves balancing performance requirements, aesthetic preferences, and budget constraints. Each wood species offers distinct advantages for specific applications.

Maple reigns supreme in professional athletic applications. Northern Hard Maple provides the dense, consistent grain structure required for high-performance courts. Its light color shows court lines clearly, while its hardness rating ensures years of reliable service under extreme conditions. COPOSPORTS biomass sport wooden flooring utilizes advanced maple processing techniques that enhance these natural properties.

Oak offers durability with character. Red Oak’s prominent grain pattern creates visually striking courts, though the grain variations can affect ball bounce consistency. White Oak provides better moisture resistance, making it suitable for facilities with climate control challenges. Both oak varieties require specialized finishing techniques to achieve professional performance standards.

Beech provides European elegance with athletic performance. This species offers hardness comparable to maple with distinctive grain patterns that create unique visual appeal. Beech requires careful moisture management during installation but rewards proper handling with exceptional durability.

Engineered hardwood expands installation possibilities. These products combine hardwood surface layers with engineered cores that resist moisture and dimensional changes. For facilities with challenging environmental conditions, engineered products offer professional performance with enhanced stability.

Professional Court Hardwood Flooring Maintenance Tips for Longevity

Proper maintenance extends hardwood court life dramatically while preserving playing surface quality. Professional maintenance programs combine daily care with scheduled deep cleaning and refinishing cycles.

Daily maintenance prevents long-term damage. Professional facilities implement dust mopping protocols using specialized equipment designed for hardwood courts. These systems remove abrasive particles that cause surface wear while maintaining the slip-resistant properties essential for player safety.

Humidity control protects wood investment. Professional court maintenance includes continuous monitoring of environmental conditions. Automated HVAC systems maintain optimal humidity ranges year-round, preventing the expansion and contraction cycles that cause gaps and warping.

Deep cleaning schedules preserve finish integrity. Professional maintenance programs include regular deep cleaning using pH-neutral cleaners specifically designed for athletic hardwood surfaces. These products remove embedded dirt and restore surface properties without damaging protective finishes.

Refinishing cycles maintain performance standards. Professional courts undergo complete refinishing every few years, depending on usage levels. This process includes light sanding to remove surface damage, followed by application of fresh finish coats that restore slip resistance and protection.

Real-World Success Stories: Professional Installations That Deliver

Successful hardwood court installations demonstrate the impact of proper planning and expert execution. These examples showcase different approaches to common challenges.

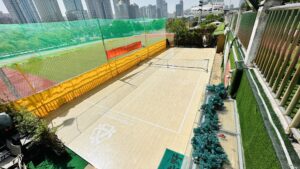

University gymnasium renovation projects often involve upgrading existing facilities to modern standards. One recent project involved installing COPOSPORTS biomass sport wooden flooring over an aging concrete slab. The installation team addressed moisture issues with advanced vapor barriers and implemented a floating subfloor system that accommodated building settlement. The result exceeded performance expectations while reducing environmental impact through sustainable materials.

Private residential courts present unique challenges combining professional performance with home aesthetics. A recent basement court installation required custom moisture management solutions and specialized HVAC integration. The hardwood installation utilized engineered products designed for below-grade applications while maintaining professional bounce characteristics.

Community center projects balance performance requirements with budget constraints. These installations often utilize cost-effective approaches that deliver professional results through careful material selection and expert installation techniques. One successful project combined locally sourced maple with innovative subflooring systems to create a high-performance court at residential project costs.

Overcoming Common Challenges: Moisture, Warping, and Wear

Professional court hardwood flooring installation requires anticipating and preventing common failure modes. Understanding these challenges enables better planning and improved outcomes.

Moisture management prevents catastrophic failures. Wood installation in athletic facilities requires comprehensive moisture control strategies. Professional contractors implement multiple barrier systems, continuous monitoring equipment, and contingency plans for unexpected moisture intrusion. These systems prevent the cupping, crowning, and gap formation that plague inadequately protected installations.

Warping prevention starts with proper acclimation. Professional wood installation protocols require extensive acclimation periods that allow lumber to reach equilibrium with installation environment conditions. This process prevents the dimensional changes that cause warping and buckling after installation completion.

Wear pattern management extends surface life. High-traffic areas experience accelerated wear that affects both appearance and performance. Professional maintenance programs identify these patterns early and implement targeted refinishing strategies that maintain consistent surface properties across the entire court.

Seasonal movement accommodation prevents structural damage. Professional court installation incorporates expansion systems that accommodate seasonal wood movement without compromising playing surface integrity. These systems use specialized transition strips and expansion zones calculated for specific geographic locations and facility conditions.

Hardwood vs. Synthetic: Making the Right Choice

Material selection decisions affect performance, maintenance requirements, and long-term costs. Understanding the trade-offs between hardwood and synthetic alternatives enables informed decision-making.

Performance characteristics differ significantly between materials. Hardwood provides natural ball bounce properties that synthetic surfaces struggle to replicate. The energy return and surface friction of properly maintained hardwood create optimal playing conditions for most sports. Synthetic surfaces offer consistency but often feel artificial to experienced athletes.

Maintenance requirements vary dramatically. Professional court hardwood flooring requires regular refinishing cycles and careful environmental control. Synthetic surfaces need replacement rather than refinishing but may require specialized cleaning protocols and periodic deep cleaning services. Long-term maintenance costs often favor hardwood installations despite higher initial refinishing requirements.

Environmental impact considerations increasingly influence material choices. COPOSPORTS biomass sport wooden flooring addresses sustainability concerns through renewable resource utilization and responsible manufacturing processes. Synthetic alternatives often require petroleum-based materials and complex recycling processes that limit environmental benefits.

Aesthetic appeal remains hardwood’s strongest advantage. The natural beauty and character of wood surfaces create inspiring environments that synthetic materials cannot match. This psychological factor affects player performance and facility user satisfaction in ways that performance metrics cannot capture.

Environmental Benefits: Sustainable Flooring Solutions

Sustainable flooring choices align performance requirements with environmental responsibility. Modern hardwood court flooring offers compelling environmental advantages over synthetic alternatives.

Carbon sequestration benefits continue throughout the product lifecycle. Wood products store carbon absorbed during tree growth, effectively removing CO2 from the atmosphere for decades. COPOSPORTS biomass sport wooden flooring maximizes these benefits through responsible forestry practices and efficient manufacturing processes.

Renewable resource utilization reduces environmental impact. Properly managed forests provide sustainable wood supplies that regenerate naturally. This renewable cycle contrasts sharply with petroleum-based synthetic products that depend on finite fossil fuel resources.

Manufacturing energy requirements favor wood products. Hardwood processing requires significantly less energy than synthetic material production. The energy-intensive chemical processes required for synthetic flooring creation generate substantial carbon emissions that wood processing avoids.

End-of-life disposal presents fewer challenges with wood products. Hardwood flooring can be recycled, repurposed, or composted safely. Synthetic materials often require specialized disposal processes or contribute to landfill accumulation.

Innovations in Hardwood Flooring Technology

Modern hardwood flooring technology continues evolving to meet changing performance and environmental requirements. These innovations expand possibilities for professional court installations.

Biomass integration represents a significant technological advancement. COPOSPORTS biomass sport wooden flooring incorporates biomass materials that enhance traditional hardwood properties while reducing environmental impact. This technology combines renewable biomass resources with proven hardwood performance characteristics.

Advanced finishing systems provide enhanced durability. New polyurethane formulations offer improved scratch resistance, faster curing times, and better UV stability. These finishes extend refinishing cycles while maintaining optimal playing surface properties.

Moisture-resistant engineering expands installation possibilities. New treatment processes and engineered constructions allow hardwood installation in previously unsuitable environments. These technologies enable professional court installation in challenging climates and facility conditions.

Precision manufacturing improves installation efficiency. Computer-controlled milling processes create more consistent lumber dimensions and better joint fit. These improvements reduce installation time while improving long-term stability.

FAQs

How long does professional court hardwood flooring installation take?

Professional court installation typically requires 2-4 weeks, depending on court size, subfloor conditions, and environmental controls required. The process includes subfloor preparation, wood acclimation, installation, finishing, and curing time before use.

What’s the expected lifespan of professional court hardwood flooring?

Properly installed and maintained hardwood courts last 15-25 years before requiring complete replacement. However, refinishing every 3-5 years maintains optimal performance throughout this lifespan.

Can hardwood courts be installed over existing concrete?

Yes, professional court hardwood flooring installation over concrete requires moisture barriers, insulation layers, and engineered subfloor systems. These additions prevent moisture problems while providing proper shock absorption and dimensional stability.

How does COPOSPORTS biomass flooring compare to traditional hardwood?

COPOSPORTS biomass sport wooden flooring combines traditional hardwood benefits with enhanced sustainability through biomass integration. Performance characteristics match or exceed traditional hardwood while reducing environmental impact.

What maintenance equipment is required for professional hardwood courts?

Professional maintenance requires dust mops designed for hardwood, pH-neutral cleaners, humidity monitoring equipment, and periodic access to floor sanders and finishing equipment for refinishing cycles.

Conclusion

Ready to Transform Your Space?

Professional court hardwood flooring represents an investment in performance, beauty, and long-term value. Whether you’re upgrading a home gym or renovating a major athletic facility, the principles outlined here provide the foundation for successful project completion.

The transition from basic flooring to professional-grade hardwood requires expert knowledge, quality materials, and meticulous execution. COPOSPORTS biomass sport wooden flooring technology offers the perfect combination of traditional hardwood benefits with modern sustainability innovations.

Don’t let your flooring project become a costly learning experience. Professional consultation ensures proper planning, material selection, and installation techniques that deliver lasting results.

Contact us today to discover how professional court hardwood flooring can transform your space into a high-performance environment that inspires athletes and impresses visitors for years to come.